ACESEAL MAX

HYBRID POLYURETHANE ELASTOMERIC ROOF COATING

ACESEAL MAX is a new technology elastomeric roof coating based on hybrid polyurethane emulsion offering a complete waterproofing protection system for more than 10 years. It forms a highly elastic, seamless membrane providing excellent protection from moisture and standing water. It has excellent adhesion to most commonly used roof substrates such as concrete, asphalt membranes, cement tiles, old insulations etc. Shows very low water uptake and high crack bridging ability for up to 3 mm crack. The coating exhibits high resistance to extreme weather conditions from -30°C/+90°C and excellent resistance to UV radiation and thermal ageing.

Fields of Application

- Colour coated steel roof, galvanized metal roofs, PEB building roofs

- Waterproofing of terraces, curved roofs, Brick-Bat Coba China mosaic tile

- Highly recommended for use in regions with low temperatures

- Ideal for the waterproofing over old bitumen waterproofing membranes

- Protection of spray applied rigid PU foam insulation

FEATURES AND BENEFITS

- Highly elastic seamless membrane with crack bridging up to 3mm

- Excellent resistance to extreme weather conditions from -30°C/+90°C

- High solar reflectance reduces surface temperature up to 10ºC

- Adheres perfectly on the substrate (concrete, bitumen, metal)

- Forms breathable coating allowing moisture to escape

- Provides dry film thickness of up to 1mm in two coats

- Long term weathering resistance of up to 10 years

- Decreases roof temperature to reduce building cooling cost

SUBSTRATE PREPARATION

Fresh masonry or concrete substrate must be allowed to cure for at least 14 days. Clean the area from all loose particles, oil, grease and any such deleterious materials. All surface cracks should be filled up with a paste of Cement and ACEGUARD BA mixed in ratio of 2:1 and applied using a trowel to seal the gaps. Ensure that the roof has minimum 1:80 slope before application of coating.

APPLICATION

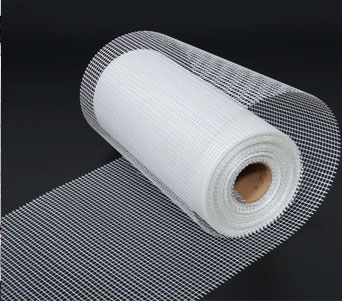

Stir well before use. Dilute ACESEAL MAX with 30% water to prepare primer coat. Apply it with roller and let it dry for 6 to 8 hrs. Apply 1st coat of ACESEAL MAX without dilution using suitable roller. Fiber glass mesh of 45 gsm is incorporated in the coating as a sandwich layer when the first coat is still in wet condition. Allow the first coat to dry for approximately 4-6 hours before applying the 2nd coat perpendicular to the first coat. Apply second coat of ACESEAL MAX without dilution using suitable roller. Ensure there are no pinholes or air bubbles in coating. Allow the system to air cure for 7 days minimum.

PACKAGING

20 Kgs Plastic Bucket. Bulk packaging available on request.

SHELF LIFE

12 months in original, unopened package

STORAGE

Store in dry area between +5°C and +35°C. Protect from heat, freezing and direct sunlight